Custom Black Anodized Titanium Bolts With Flange Head For Sports Or Racing Equipment

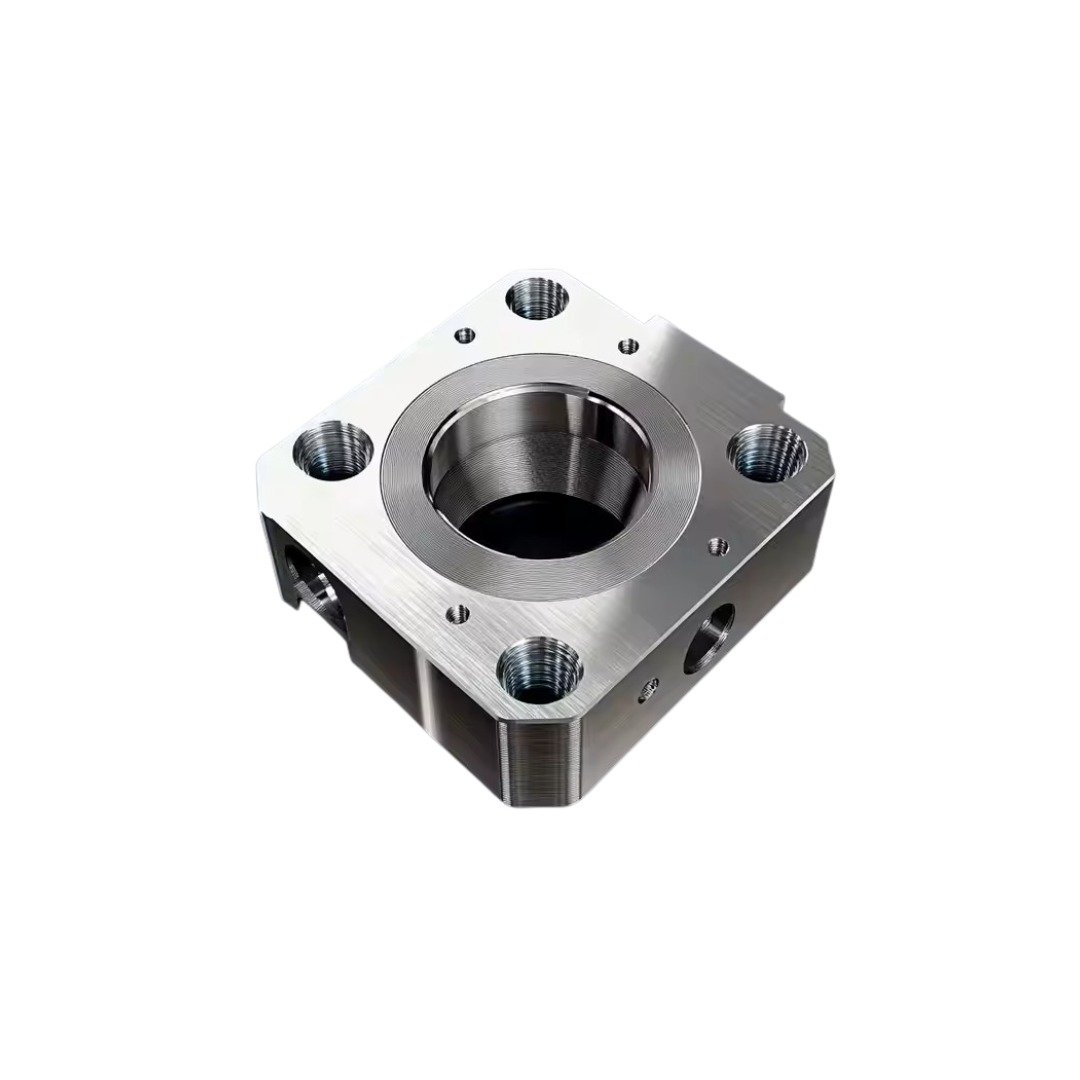

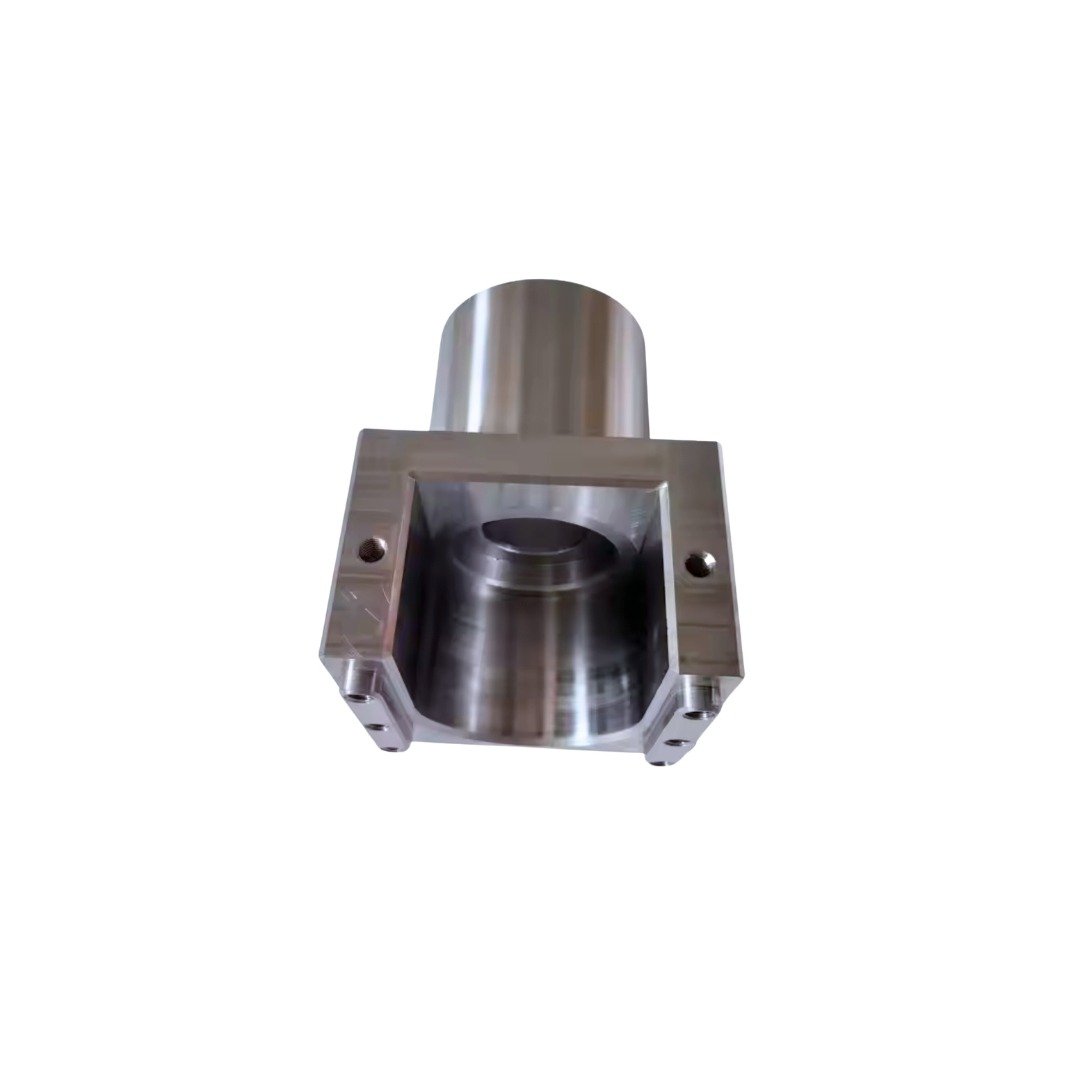

CNC Machined Titanium Parts

Strong, lightweight, and built for performance.

-

High Strength-to-Weight Ratio

-

Exceptional Corrosion Resistance

-

Biocompatibility for Medical Use

-

Precision Machining Capability

-

Durable Surface Options

-

Reliable Performance in Harsh Conditions

Digital Manufacturing from Early Prototyping to Final Production

Your Fast, Full-Service Manufacturing Partner.

Get instant quotes and expert support from design to production.

Why Choose Us for Custom CNC Machining?

As a trusted manufacturer of precision machined components in China, we specialize in CNC Machining, CNC Turning, CNC swiss maching and metal fabrication. We are committed to delivering high-quality, custom-engineered parts to meet your exact specifications.

- Fast and Reliable Delivery

- Manufacturing Analysis and Online Quotes

- High Capacity

- Material Selection

- Advanced Capabilities