Online CNC Machining Service

Your Fast, Full-Service Manufacturing Partner.

Get instant quotes and expert support from design to production.

CNC Machining for Prototyping to Production

With our factory and multiple partner suppliers,

we have a very broad range of manufacturing capabilities and support both one-off prototyping and low-volume production.

We pride ourselves on being the go-to manufacturer for geometrically complex parts or highly cosmetic parts.

Get an instant CNC machining quote

Online CNC Machining Service

Compare our CNC machining services designed to meet the needs of every stage of the product lifecycle.

- Aluminium Alloy Machined Parts

- Stainless Steel Machined Parts

- Brass& Copper& Bronze Machined Parts

- Steel Alloy Machined Parts

- Titanium Alloy Machined Parts

- Plastic Machined Parts

CNC Machining Capabilities

CNC Milling

CNC milling is a subtractive

manufacturing process that

uses 3-axis, 4-aixs and

5-axis indexing to cut solid

blocks of plastic and metal

into finished parts.

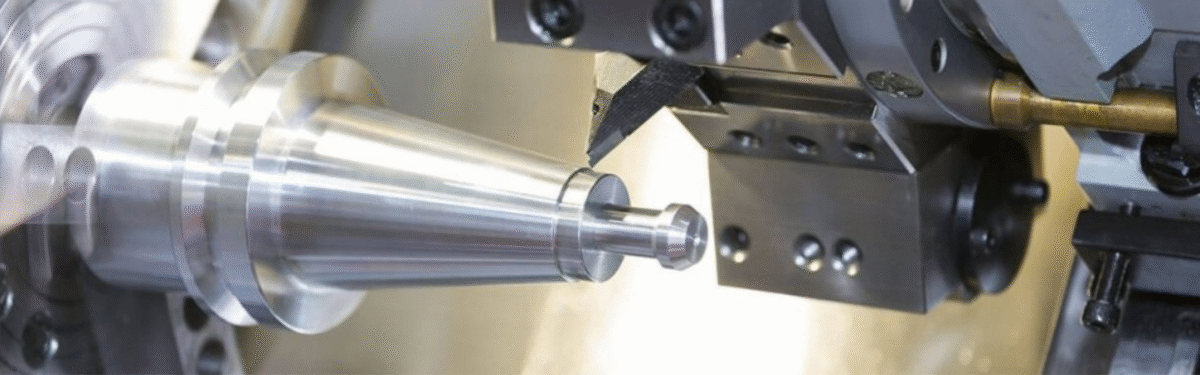

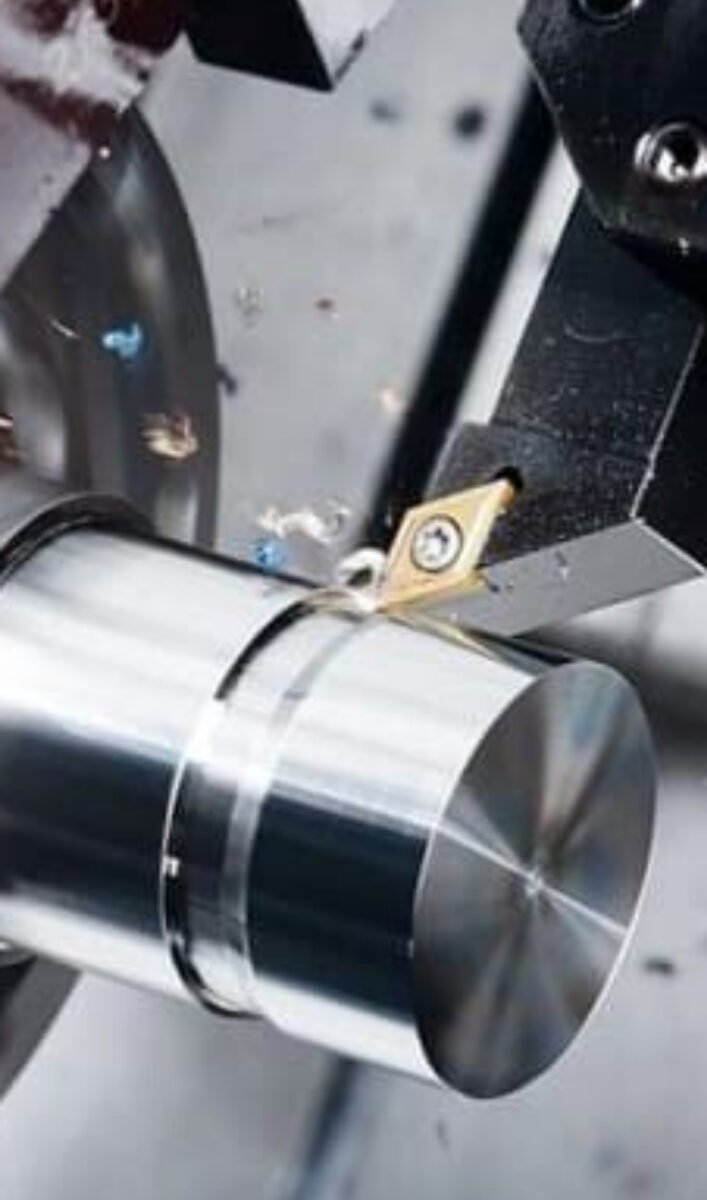

CNC Turning

CNC turning with live tooling primarily utilizes lathe – turning functions. It enables the machining of parts with cylindrical features from metal rod stock.

CNC Swiss Machining

CNC Swiss machining specializes in high- volume production of small-sized and slender metal parts. Leveraging its unique design, it features automatic loading and cutting functions.

CNC Milling

CNC Turning

CNC Swiss Machining

Metal Fabrication

Laser Cutting

Laser cutting utilizes a high-intensity laser beam to deliver fast and accurate cuts on metal sheets. This non-contact process ensures clean edges and minimal material waste, making it ideal for complex and high-precision parts.

Forming and Bending

Forming and bending apply controlled force through a die and punch to shape metal along a straight axis. It’s widely used for creating uniform bends in sheet metal with high repeatability and structural integrity.

Metal Extrusion

Metal extrusion involves pushing sheet metal through a die using consistent pressure to form linear features or channels. This method is efficient for producing parts with continuous cross-sections and enhanced strength.

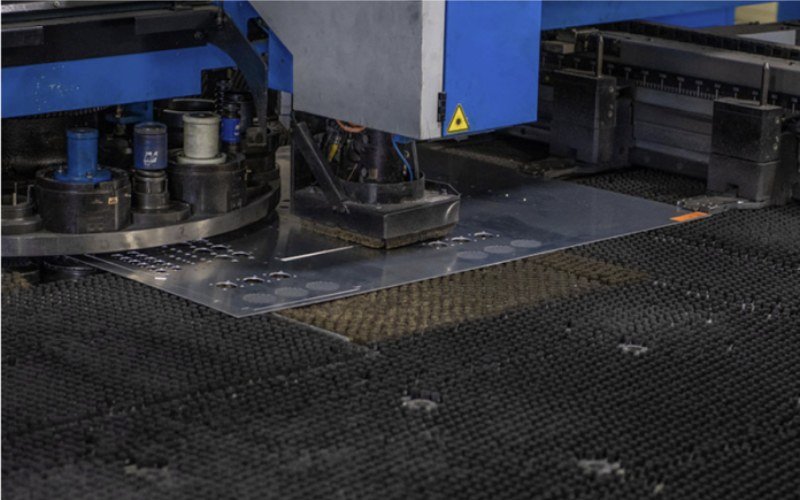

Punching and Stamping

Punching and stamping rapidly shape or cut metal sheets by pressing them between a punch and die. This high-speed process is suited for mass production of detailed or repetitive metal components.